rp+m Helps Students Create 3D-Printed Rocket Section

by Dana Foster

rp+m

Rapid Prototype and Manufacturing (rp+m), Avon Lake, Ohio, collaborated with a local high school to help design and manufacture a 3D printed rocket section. This year, St. Vincent-St. Mary, located in Akron, Ohio, was one of eight high schools across the country selected by NASA to participate in its 2014-2015 NASA Student Launch Challenge.

The students proposed to build a rocket using additive manufacturing techniques and carbon fiber composites while carrying a payload that consisted of a computerized pitot tube used to measure the vehicleís air speed. Students chose these manufacturing methods because they allowed for the design and construction of very high strength-to-weight-ratio components that could not be made using traditional methods.

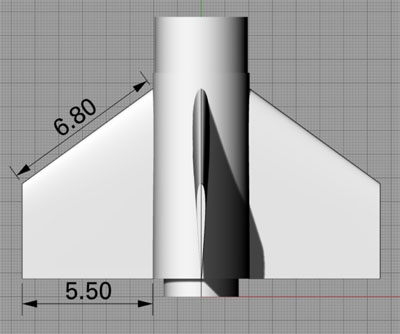

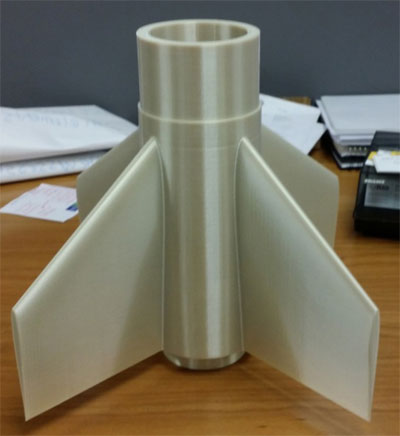

Students came up with the initial design of the rocket, but needed a partner to help them finalize the product. St. Vincent-St. Mary students sent their design to rp+m and they worked together to finalize the design and material selection. The students worked with rp+mís design engineering team to construct parts that are much lighter and use less material while still maintaining the structural integrity demanded by the function. The aft unit of the rocket, which consists of the booster and fin section, was made of ULTEM*9085, which provides high tensile and compressive strengths as well as high temperature resistance.

The rocketís body was made from carbon fiber composite materials. These materials also provide for very high material strength-to-weight ratios, which are very important to the aerospace industry. Lighter, stronger vehicles make it possible to lift larger payloads while using smaller amounts of fuel.

In addition to designing and constructing the rocket using advanced manufacturing techniques, the team also designed an engineering payload – a pitot tube. It works on the principle of measuring differential air pressure to calculate air speed and generate a profile of the rocketís flight. The pitot tube was designed to fit into the nose of the rocket and retract during descent and landing to prevent damage to the instrument. Students used off-the-shelf computerized components and pressure sensors to construct the apparatus and calibrated it in a wind tunnel housed in the schoolís engineering lab.

The team also raised almost $10,000 to construct the rocket and pay travel expenses for an April trip to Huntsville, Alabama, where they will showcase the rocket for the engineers at the NASA Marshall Space Flight Center. The project was funded by donations from individuals and companies.

For more information, visit www.rpplusm.com or www.stvmsli.com.